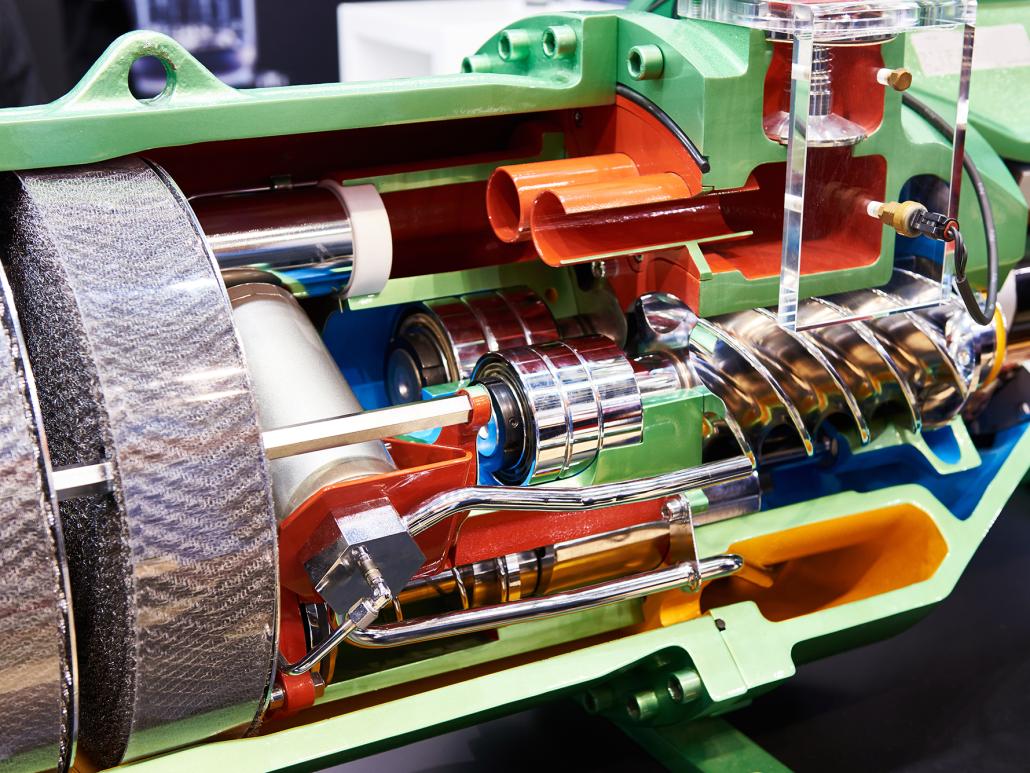

Reduce energy costs Having the air compressor well-lubricated reduces friction, which may result in wear and excess heat. Typically, the compressor’s parts like rotors, bearings, gears, cylinders, and sliding vanes cause more heat as they move. At the same time, it needs a lot of energy to cool the unit and allow for safer functioning. With proper lubrication, power usage and energy costs get reduced drastically. More importantly, it ensures that everything keeps on working efficiently without wearing out. As a result, lubrication reduces the risks of breakdown and repair and maintenance costs. Prevent rusting and corrosion The air compressor is often susceptible to rusting and corrosion, which may damage or block the parts. And this can result in poor…